創新的供應解決方案通常會導致流程簡化和精益製造成本削減。在一個特定案例中,我們實現了具有里程碑意義的 0% 短缺率。

真實結果,真實影響

0%

短缺率

情況

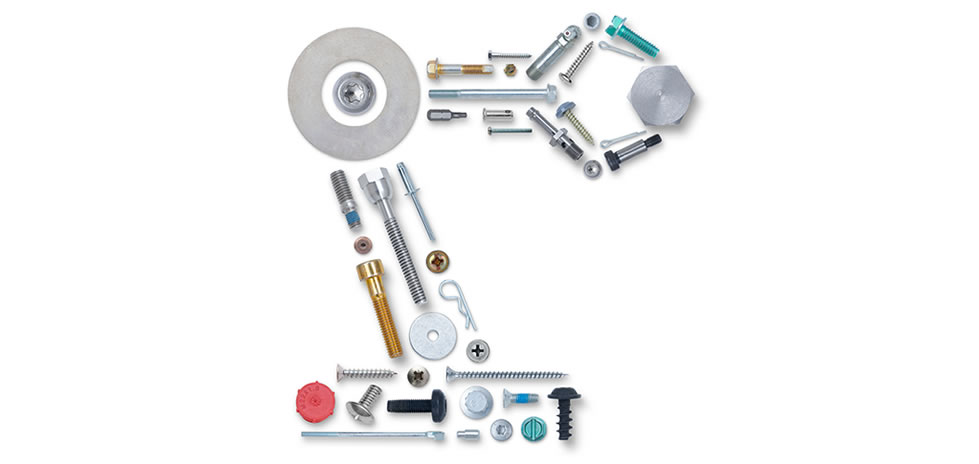

當製造生產線出現短缺時,業務目標和生產力就會受到影響。除了標準緊固件之外,我們還與客戶合作,通過印刷材料、標籤和成套材料來消除和防止生產線短缺和延誤。

解

Optimas 開發了正確的庫存管理程序組合,為所有材料接收、存儲和部署建立了一個單一的控制點。並且,駐當地的特使立即開始提供日常線路服務,以確保沒有間隙。

結果

客戶減少了對組件的資本投資,並能夠增加設施空間,同時重新部署釋放勞動力以提供更好的客戶服務。