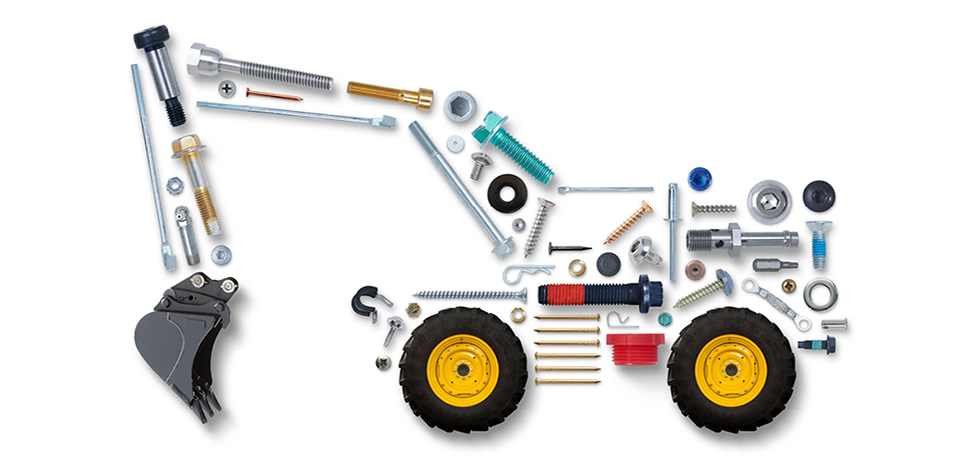

Optimas 為新的挖掘機生產線提供了流線型的防腐蝕和摩擦一致性策略,同時提高了整體成本節約。在我們的幫助下,客戶節省了超過 30% 的裝配流程時間。

真實結果,真實影響

30%

降低裝配成本

10%

駕駛室重量減輕

情況

一家領先的建築機械製造商尋求減輕其最新型號駕駛室的重量,以此作為將每台機器的效率平均提高數百美元的方法。

解

我們的工程師從設計階段的早期開始就將他們的專業知識和創新方法應用到質量和耐久性測試中。他們走在客戶的生產線上,發現了減少裝配過程的機會。此外,我們的區域質量實驗室在確保我們提出的緊固解決方案耐腐蝕同時提供滿足客戶要求的摩擦一致性水平方面發揮了重要作用。

結果

我們的工程師將裝配工藝成本降低了 30% 以上。此外,我們的深入分析和解決方案測試使駕駛室重量減輕了 10%,最終節省的成本遠遠超過原始 BOM。