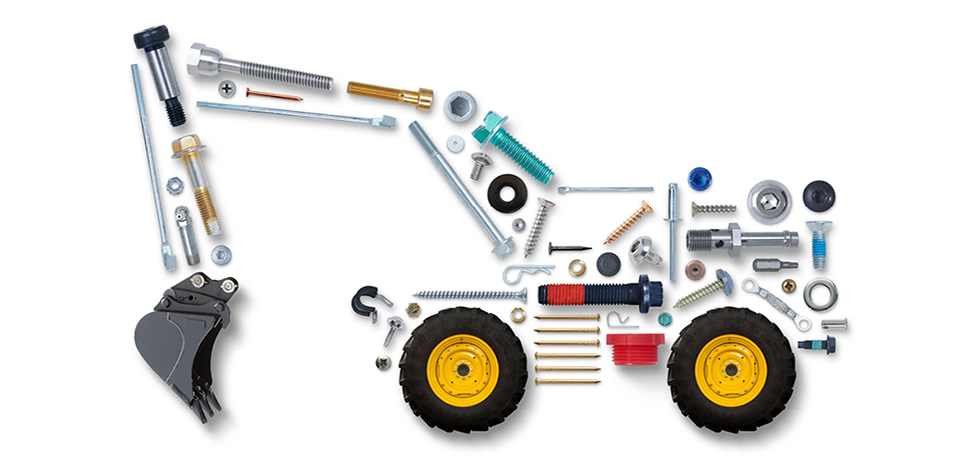

Optimas delivered a streamlined corrosion prevention and frictional consistency strategy for a new excavator line, all while improving overall cost savings. With our help, the customer achieved savings of over 30% in assembly process time.

Real Results, Real Impact

30%

Assembly Cost Reduction

10%

Cab Weight Savings

Situation

A leading manufacturer of construction machinery sought to reduce cab weight in their newest model as a way of increasing the efficiency per machine by an average of several hundred dollars.

Solution

Our engineers applied their expertise and innovative approach starting early in the design stage through to quality and durability testing. They walked the customer’s line and identified opportunities to cut assembly process. Additionally, our regional quality laboratories played an important role in ensuring our proposed fastening solution was corrosion resistant whilst providing the level of frictional consistency that met the customer’s requirements.

Result

Our engineers cut assembly process costs by over 30%. Plus, our deep level of analysis and solution testing enabled a reduction of cab weight by 10% with final cost savings well beyond the original BOM.