隨著電動汽車行業的發展,製造商的庫存手冊需要什麼?

電動汽車產業呈指數級增長。首先,電池成本下降導致電動車購買量下降 增加 43% 僅在一年前,另一項研究預測 全球所有乘用車銷量的 57% 到 2040 年將實現電動化。

隨著電力銷售量的增加,相互競爭的能源正朝著相反的方向發展。預計到 2030 年 將被禁止 生產新型汽油和柴油動力乘用車。

需求的成長意味著開發流程和電動車供應鏈需要簡化,甚至可能需要重新構想。例如,電動汽車緊固件佔 50% 工業製造 SKU and are essential to the vehicle’s infrastructure and its maintenance equipment. How can EV startups improve inventory management and build an array of lightweight, insulated, and cost-effective fasteners that keep up with industry demands? Here are a few solutions:

儘早與經驗豐富的合作夥伴合作

Team up with a specialist that offers a complete end-to-end experience. This partner should be able to handle design and engineering, BOM analysis, part consolidation, and be able to identify cost-saving opportunities that help you scale quickly and reduce waste.

選擇一個能夠滿足您的可用性、複雜性和物流需求的合作夥伴。此外,確保合作夥伴專注且注重細節,以與生產時間表保持一致,而無需在此過程中停頓太多。

了解您的開發週期

最常見和破壞性的緊固件庫存管理問題發生在供應鏈過快地完成緊固件供應時。如果單個緊固件需要長達 20 週的時間才能完成開發週期,那麼可用性的任何變化都會使項目倒退。

透過了解您的開發週期來縮短交付週期。做好計劃,並確保您的合作夥伴有處理您可能需要的獨特類型緊固件的經驗。

考慮增材技術以提高可測性

通過一系列測試和迭代來開發您的項目可能更有意義。構建原型,對其進行測試,並創建更具成本效益的大規模生產方式。

添加劑的做法,如 3D打印 可以透過縮短上市時間來幫助此方法發揮作用。嘗試虛擬原型,看看哪些可以堅持下去。然後,將這些模型的規格轉化為成品,使您的車輛既輕又實用。

電動汽車庫存管理不善如何影響成功

這對電動車產業的成長有何影響?

In 2018, just 2 million units were sold. In 2025, that figure is expected to jump 400% to 10 million sales.

Learning how to manage the invaluable pieces with the electric vehicle supply chain (e.g. fasteners, c-class components) will be critical for companies looking to succeed within the market.

庫存不匹配的後果

For challengers in the fast-growing EV industry, it’s not enough to manage whole product supply chains, you need a set of inventory management strategies to avoid problems like:

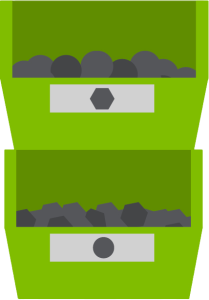

標籤錯誤的垃圾箱:

Inventory organisation is a big reason supply chains go awry. Mislabelling Just-In-Time (JIT) and Kanban bins can lead to contaminated stock. A mislabelled bin leads to the wrong parts being used, which leads to significant supply chain hiccups.

浪費時間:

Every minute lost during inventory management adversely impacts the bottom line. When you don't clearly understand the timeline of different fasteners, components and 維修、維修及大修, it's easy for a delivery logjam to form.

供應短缺:

Without parts, there are no products. Tesla ran up against this problem when it's supply chain lacked the cells necessary to create the vehicles' batteries. Production needs an availability, or an abundance of raw materials and parts. Without them, your operations could grind to a halt.