供应链管理的 3 个技巧:扩大规模

现在,制造商比以往任何时候都更加了解他们的供应链。这种认识引发了许多关于如何提高效率和弹性的问题。我从事分销和供应链专业人士近三十年,因此我了解平衡供应连续性和客户需求的挑战。由于 COVID-19 暴露了即使是最安全的供应链中的漏洞,供应链经理正在应对日益复杂的情况。了解如何简化复杂领域并稳定薄弱环节将使您能够随着需求的变化快速扩大或缩小规模。以下是一些常青提示 简化您的零件管理 for a stronger, more resilient supply chain.

简化零件管理的 3 个技巧

关键要点:寻找供应线具有可见性和安全性的供应商,并获得必要的技术支持,无论疫情如何都能管理未来的需求。

1. 寻找标准零件的单一来源

选择单一来源的标准零件是降低供应链复杂性的坚实第一步。寻找经验丰富的合作伙伴,可以扩大或缩小规模以满足您的需求,最好是与多个地区管理严密的合作伙伴合作。

2.选择速度和辅助功能

一旦您整合了您的供应商网络,请确保留在船上的每个人都有资源(技术、人员和财务稳定性)来满足您在扩大规模时的产出。您的供应链合作伙伴应该高度可靠、易于接近并专注于您的需求。他们应该能够兑现为您最常用的部件快速、轻松订购的承诺。无论是面罩还是冰球,相信您的合作伙伴可以交付是最基本的品质。 (是的,我们遇到了冰球的紧急呼叫。它发生了。)这就是合作伙伴所做的。

3.需求实时数据

Along with consolidating your suppliers and vetting them for speed and reliability, ask them how they can support you with real-time visibility into your supply chain. Real-time production and shipment visibility can help you be proactive about gaps or potential disruptions to your supply chain–both critical to scaling up. Knowing where your parts are, what you’re running low on, and what you’re overstocked on will help you streamline your parts management and avoid costly disruptions to your supply chain.

额外提示:寻找财务稳定的供应商

即使是最积极响应、以客户为中心的合作伙伴也可能容易受到外部力量的攻击。不幸的是,自疫情爆发以来,我看到许多供应商倒闭了。你最不希望看到的是与供应商建立关系,却在市场急剧左转时看到他们倒闭。寻找具有 经过验证的财务稳定性 它不仅可以和你一起渡过难关,还可以在遇到困难时帮助你前进。

关于重新支持标准零件管理的简短说明

COVID-19 仍在影响零件管理,制造商对回流、区域化或在其供应链中使用“中国+1”模式的兴趣日益浓厚。

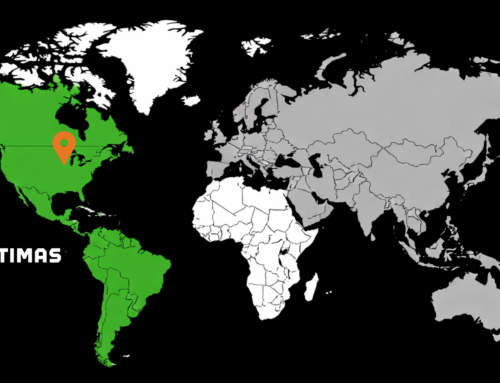

As a matter of fact, Optimas recently opened a new distribution center in St. Louis to support manufacturing customers who need reliable, fast delivery of standard parts. This strategic location, in the middle of the country, along with a robust supply chain and vendor portfolio, has proven invaluable to customers. It has allowed them to scale with customer demand, improve cash flow, and minimize risks in a time when their competitors are struggling with lockdowns in Europe and delays from China.

让您的供应链为接下来的一切做好准备

如果说 2020 年教会了我一件事,那就是我们的世界已经发生了变化,并将在未来继续发生变化。即使有了疫苗,各大洲的制造工厂也将继续遵守更高的安全规程。这意味着对其他消耗品的需求也将持续存在,例如 PPE 和消毒产品。

您可以通过与能够提供标准零件和 个人防护设备和 MRO to stay safe and operational. Have a look at what Optimas is doing with all three of these consumables at us.optimas.com.