可持续供应链的在岸和近岸外包

对于希望实现可持续生产实践并实现净零碳排放目标的企业来说,了解供应链至关重要。供应链对于制造商和分销商来说至关重要,但它们可能错综复杂且不可靠。

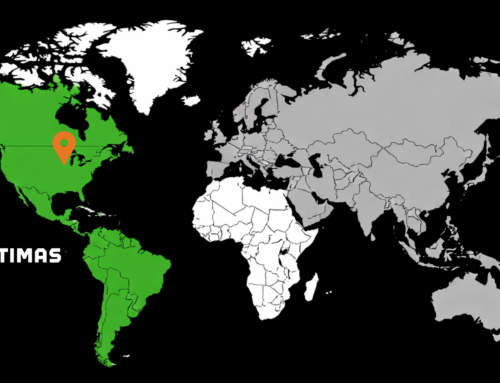

Unfortunately, there’s no easy way to fix supply chain instability. Making a supply chain sustainable is also a long process. What may be more feasible, however, is attempting to reimagine how these workflows operate — and onshoring or nearshoring 可能是答案。

How Do Onshoring and Nearshoring Impact Sustainability Measures?

Onshoring is when all supplies are sourced from the manufacturer’s home country. Onshoring improves the control companies have over their parts, production schedules, and quality. It also allows companies capitalise on sustainability by improving their carbon footprint.

Nearshoring is similar to onshoring, but it instead involves sourcing materials from neighbouring countries. It still lowers supply chain risk by cutting transport time and it enables closer cooperation between parties.

那么在岸外包和近岸外包如何带来切实、可持续的成果呢?

- 本地采购可减少运输

通过在岸或近岸外包,零部件和材料无需长途运输。这减少了对多种运输方式的需求,尤其是运输大量碳排放的运输方式,如货机和轮船。

考虑到 全球温室气体排放量17% 来自货物运输,当地采购是实现可持续制造的好方法。

- 生产变得更加灵活

生产计划经常会因为供应链而打乱。物流流程需要很长时间来规划,一旦被打乱,就会造成混乱。

由于本地化来源缩短了您的供应链,您将有更多的空间来研究和开发您的生产流程。

This more demand-centric model allows businesses to quickly respond to problems, cut waste, and better serve consumers. This then frees up business to use sustainable manufacturing practices.

- 供应链变得更加人性化

在岸和近岸外包的一大优势是,它们能够通过更紧密的沟通和协作,将供应链合作伙伴团结起来,并使他们专注于共同的目标。

您的供应链将变得更加透明。此外,与其他企业合作对于减少制造业的碳排放至关重要。

在岸和近岸采购可以帮助您建立更可持续的供应链。 Optimas Solutions 生产高品质紧固件 对于寻求可持续采购的 OEM 来说很有价值。