更好的 BOM 是否等于更好的业务? (剧透警报:是的)

提升将产品从概念推向市场的过程包括在整个生产生命周期中尽可能清洁的物料清单 (BOM)。

通过确定 BOM 的优先级并制定适当的 BOM 管理策略:

- 零件合理化工作变得更容易,并进一步降低成本

- Efficiencies across product lines improve to the company's and customer's benefit

- 与供应链合作伙伴的沟通得到改善

- 消除浪费的软成本,例如在数据库中维护无关的部件(估计每个部件 $1,600)

- 整合采购、供应链和运营等业务职能

如果这些好处听起来很吸引人,请继续阅读并了解真正好的 BOM 可以为您的业务做些什么:

BOM 消除噪音

零件生产需要自始至终的问责制——适当的 BOM 使之成为可能。我们称其为事实的单一来源。准确的 BOM 减少了生产过程中的混乱和低效率——以及与识别缺失部件相关的噪音。

Basically, it boils down to ensuring people at your company are communicating with the right people across the supply chain and you're properly documenting the steps taken throughout the process. The more you can point to your BOM, the fewer possible issues can pop up. This includes part changes that occur throughout the production lifecycle.

通过保持 BOM 的准确性,您可以维持可用性、确保问责制并为您自己和您的供应链合作伙伴营造对最终产品的主人翁意识。

更好的 BOM 带来更好的关系

您的 BOM 可确保所有部门和供应链合作伙伴协同工作。它是制造和精度计数中最值得信赖的文件之一。

A well-defined BOM brings order to the production process. It's common for multiple departments—engineering, purchasing, operations—to all work from the same BOM. For this reason alone, it's important for product leaders to make sure that the BOM is accurate from the beginning.

您可以通过积极主动地设计一个完整的 BOM 来最大程度地减少挫败感,该 BOM 可以回答生产和财务主管、您的供应链合作伙伴甚至分销渠道主管不可避免地会提出的问题。

想要节省更多成本?强化您的 BOM

Cost savings can pop up in any number of ways during the production process. BOMs answer questions about materials, parts, assembly, and quantities. With that information, experts like Optimas' engineering and supply chain teams can:

- 预测最佳生产和劳动力安排

- 确定准确的产品定价

- 调整使用率以最大限度地减少库存和零件过剩

- 确定可能的零件整合

- 采购更实惠的材料

- 找到质量更好的材料

- 针对现有流程开发定制解决方案

- 创建新流程以加快生产并缩短交货时间

- 提供重新设计选项和解决方案以应对持续的挑战

It's a real eye-opener when customers see how an accurate BOM can create so many more paths to operational savings and production success. At Optimas, our tagline is 效率提升 because that's what we deliver every day. With a detailed and clearly illustrated BOM on the front-end, manufacturers gain access to a mountain of savings down the road.

最后的想法

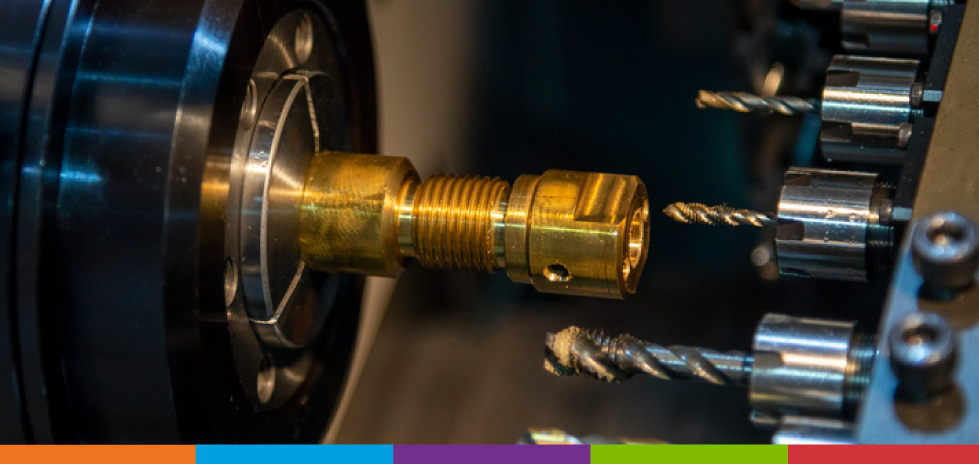

客户依赖 Optimas 团队的采购专业知识, 制造能力, 和 技术支持的库存制造解决方案 我们提供。这些依赖于完整和准确的信息。您的 BOM 就像我们制造的紧固件一样,是您运营的基础。

If you're looking for advice for creating better Bills of Material for your process manufacturing business, drop us a 笔记 继续讨论。 Optimas 可帮助您提高效率。