Improving Inventory Management for EV OEMs

It’s predicted that by 2026, 95% of companies will continue to use outdated supply chain models and that will prevent them from achieving end-to-end resiliency in their supply chains. In addition, the electric vehicle (EV) market is set to grow at a CAGR of 33.6% from 2024 to 2030, meaning that robust inventory management is more important than ever to help manage this increase in demand.

Despite the significant market opportunity, rising material and energy costs alongside disrupted trade routes are hindering the progress of EV OEMs. However, distributors are constantly adapting to these challenges and optimizing their inventory management processes to mitigate supply chain risk so their partners can meet demand.

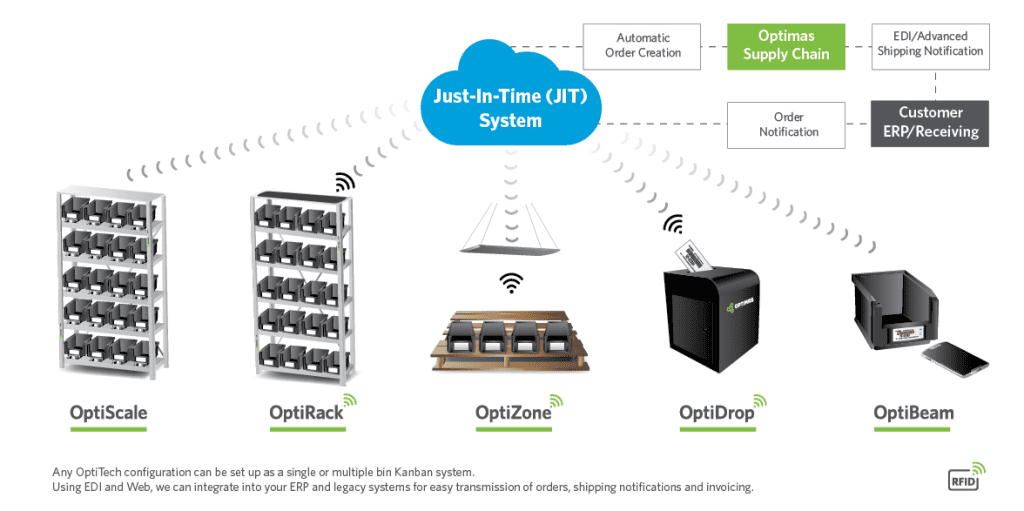

With over 100 years of experience manufacturing and distributing fasteners to a range of industries, including EV, Optimas is an expert at reducing risk and elevating output. Employing advanced cloud-based technology, our OptiTech 庫存管理解決方案 ensure availability and boost operational efficiency.

Master Your Data Management

When it comes to assessing supply availability, EV OEMs must have good, clean supply chain data, transparent and realistic demand forecasts and production schedules.

Automated collection of usage data, in real time, will bring inefficient inventory management processes into focus and enable EV OEMs to make smarter decisions and re-task teammates to higher value activities. This can be done in one of two ways:

- Designating a person or department to oversee supply chain data

- Working with a third-party supply partner to manage that information and apply it to current inventory management processes

Supply partners, like Optimas, have experts who can assess current processes and identify an EV OEMs specific need for a digital inventory management system. From learning about their ideal replenishment intervals to understanding typical quantities for reordering, these experts can find solutions tailored for their requirements.

Our OptiTech inventory management solutions use real-time data and predictive analytics to automate inventory replenishment, meaning you’ll always have the right parts, at the right time. 點擊這裡 了解更多。

Implement Forecast Models and Plan for Demand

Inventory forecasting is invaluable for EV OEMs, especially in times when consumer demand and supply chains are evolving rapidly. The best forecasting uses a mix of real-time, quantitative (e.g. past numerical insights) and qualitative data (e.g. market trends, product lifecycle) and provides procurement teams with the flexibility to make more accurate inventory acquisition decisions.

This insight enables supply chain teams to see where the demand is coming from and plan accordingly. As a result, EV OEMs can see adjust production up or down based on demand and product availability in the supply chain.

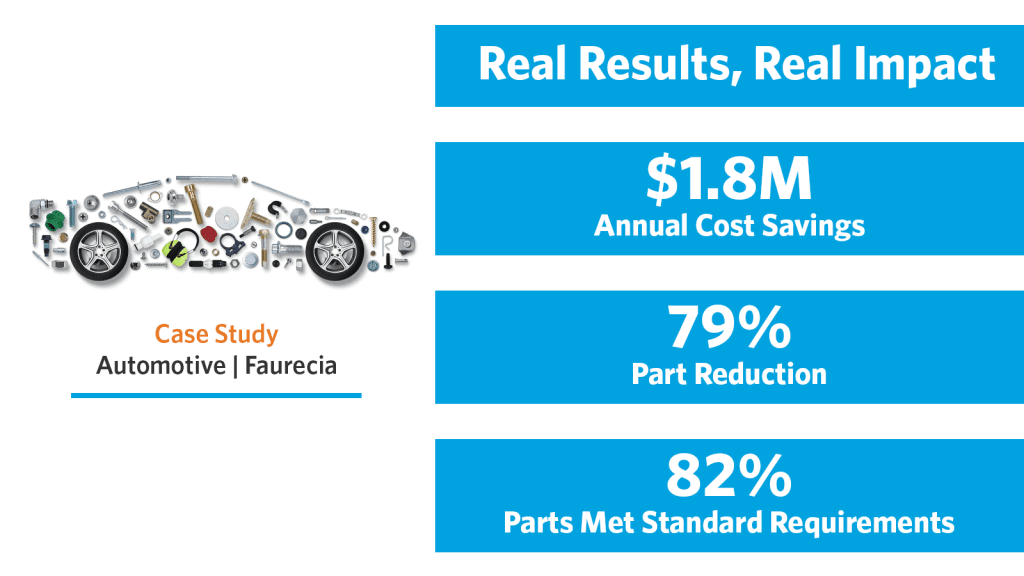

Optimas, prioritizes data transparency, providing our partners with an unparalleled insight into demand and product availability. Producing both standard and customized reports, we supply a thorough understanding of our partners’ inventory usage, including information like BoM profiles and inventory turns.

點擊這裡 to learn how Faurecia, a global manufacturer of interiors, seating, and emissions solutions, partnered with Optimas to define a standardized global part catalog, leading to significant efficiency gains, cost savings and speed to market.

Outsourcing Automated Solutions

Full-service distributors, with robust inventory management services, possess the necessary tools to support demand planning and optimize on-hand inventory to meet production requirements. Visibility illuminates potential issues before they become problematic, and that’s what EV OEMs should look for in a full-service supply partner.

We work with EV OEMs to help optimize their inventories . Our five OptiTech solutions provide access to tech-enabled acquisition processes and customized reports for greater transparency into your inventory and consumption data. All OptiTech configuration works with a single or multiple-bin Kanban system. Built-in EDI and web tools integrate into existing ERP and other production systems for easy processing of orders, shipping notifications and invoicing.

Achieve End-to-End Supply Chain Visibility

EV OEMs evolving to current and future demand need automation and adaptability to improve their supply chain resilience and achieve production goals.

A tech-enabled inventory management system, tailored to their specific business needs, can provide procurement-to-pay visibility. Learn more about improving management systems and how EV OEMs can improve their supply chain by contacting Optimas, and one of our experts will get in touch to help solve your query.

You can also continue reading our inventory management resources, which we have put together to address the most common challenges we face every day.