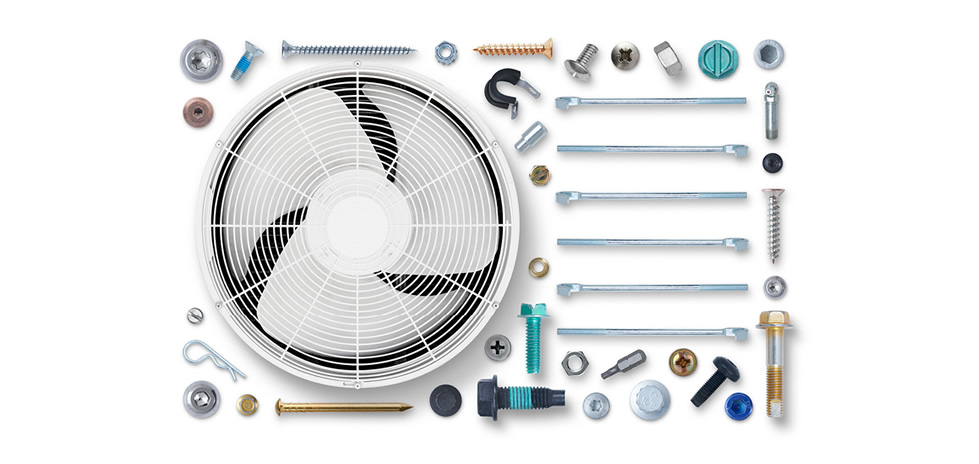

Optimas Solutions increased manufacturing and supply efficiency by introducing an integrated methodology for this pool heater manufacturer. Consolidation and simplification of component related activities via lean principles delivered tangible advantages to its production operations.

Real Results, Real Impact

1

Consolidated Monthly Invoice

Situation

The manufacturer wished to reduce its investment in components, while simultaneously strengthening the supply chain through simplification. Furthermore, the business needed to ensure that this new framework could still deliver the required components reliably to the production line via a lean approach.

Solution

Optimas introduced a fully integrated Vendor Managed Inventory (VMI) program to deliver components daily to the line. Applying lean delivery principles via a Just-In-Time (JIT) methodology, the tailored supply system fit the manufacturer’s requirement. To further improve consolidation, Optimas included non-traditional fasteners, printed materials, labels and kitted materials to encompass all of the manufacturer’s component needs within a single framework.

Result

The lean supply framework reduced capital investment in components, while daily line deliveries also served to increase on-site inventory space. Improved efficiency and Optimas supply management allowed labor to be assigned more effectively, allowing greater focus on other aspects of the business. Shortages and delays were eliminated, boosting uptime. A single point of contact for all component concerns enabled ease of communication and a single consolidated monthly invoice.