Navigating Tariff Uncertainty: A Strategic Approach for the Fastener and Components Supply Chain

As global tariff announcements continue to reshape trade dynamics, businesses across manufacturing, engineering, and distribution are being forced to reconsider how they source and manage essential components. For those operating in the industrial fasteners and C-class components space, the challenge lies not only in cost exposure but also in ensuring continuity of supply—without disruption.

At Optimas, we understand the complexities that tariffs introduce to the fastener and components supply chain. With many products traveling through international routes and involving multi-tiered sourcing, even modest changes in trade policy can have disproportionate effects on availability, lead times, and landed costs.

Understanding the Impact—Before It’s Fully Known

One of the most difficult aspects of the current climate is the uncertainty. While the specifics of tariff implementation may take time to materialize, inaction is not an option. Delayed responses can create backlogs, drive up costs, or compromise critical customer operations.

That’s why we’re already taking action—before the full picture emerges—to model different scenarios and activate mitigation strategies across our global fastener supply chain. These include:

- Reviewing supplier and country-of-origin exposure to flagged tariff categories

- Engaging with key suppliers to share risk and secure favorable terms

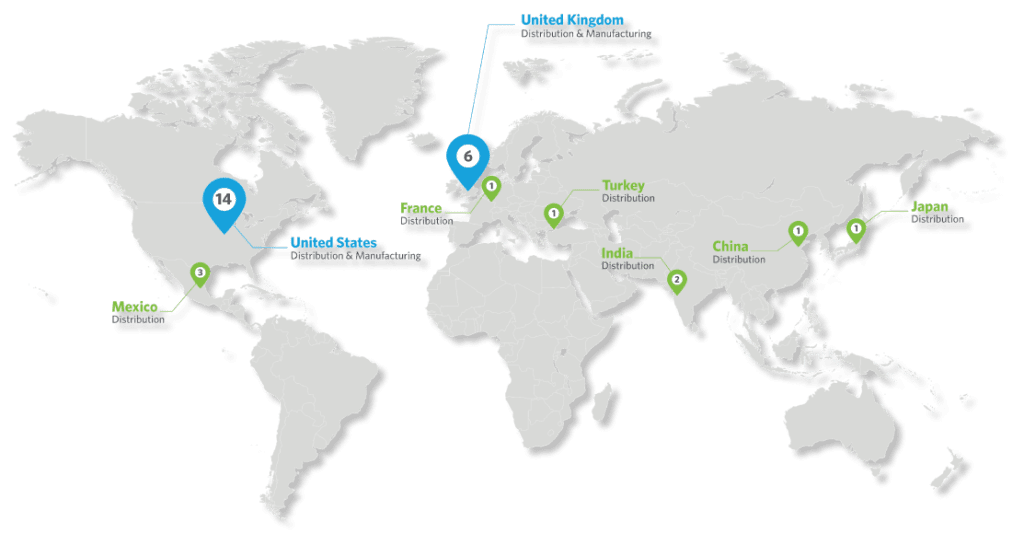

- Exploring alternate sourcing strategies for tariff-impacted regions, including reshoring/onshoring and nearshoring using our own in-house cold-form manufacturing facilities in the U.K. and the U.S.

- Utilizing Vendor Managed Inventory (VMI) models to hold buffer stock closer to customer sites

- Leveraging our multi-region warehousing to adjust fulfillment strategies

Mitigating Risk with Smart Inventory & Sourcing

For customers who rely on a steady stream of C-class components, even minor delays can ripple across production schedules. Our inventory management programs are designed to reduce this risk by improving visibility and shortening response times. Where appropriate, we’re working with customers to review their usage forecasts and pre-position critical stock in strategic locations.

At the same time, our sourcing and compliance teams are reassessing product classifications across regions—HTS (Harmonized Tariff Schedule) codes for the Americas, HS Tariff codes for the UK, and commodity codes for the EU—to ensure alignment with current tariffs. We are also exploring opportunities for duty re-engineering, both of which can deliver significant cost advantages.

Working Together Through Uncertainty

We believe that fastener distribution isn’t just about parts—it’s about partnership. Now more than ever, it’s essential to have a supply partner who’s proactive, transparent, and focused on long-term value.

If you’re concerned about tariff exposure in your fastener categories—whether for standard components veya custom-engineered parts—our team is here to help you navigate what’s next. Connect with an expert today, and together we can chart a path that protects your supply chain and positions you for growth despite the challenges ahead.