Barton Cold-Form, an Optimas company, prevented a line shutdown for a major OEM with a

rapid response that compressed a six-week lead time to just six days.

真实的结果,真实的影响力

6

Day

Lead Time

Reduced From

6 Weeks

0

Line

Stoppage

Rapid

Intervention

100%

Customer

Satisfaction

Barton’s Agility

Recognised

BACKGROUND

When an unexpected IT error at a key customer risked halting a major OEM production line, Optimas’ UK manufacturing division, Barton Cold Form, rose to the occasion. With a tool change, overnight production, and local subcontractor collaboration, a six-week lead time was compressed into just six days

CHALLENGE

In April 2025, at 8pm on a Wednesday evening, a critical request came in: due to a customer-side technical error, a major OEM line was about to run out of essential externally threaded fasteners. Without a rapid intervention, production would grind to a halt within the week.

ACTION

Backed by a clear directive from the Optimas CEO — “Do what you have to do to ensure the line doesn’t stop” — the Barton team immediately diverted production plans.

- A full tooling changeover, normally requiring eight hours, was completed in four.

- Staff returned on-call from home, working through the night.

- By midnight, production was running, covering one week’s worth of stock by dawn.

- Subcontractors within a 30-mile radius were activated to plate, phosphate, and harden the parts the same day.

- Parts were inspected, packed, and shipped to the customer by 6am Monday.

RESULTS

- Lead time reduced from six weeks to less than six days.

- No line stoppage.

- Full customer satisfaction and recognition of Barton’s agility.

Optimas’ strategic investment in UK manufacturing through Barton Cold Form paid off. With suppliers and subcontractors located within 30 miles of the plant, Barton was able to respond with unmatched agility and speed.

“This is what UK manufacturing excellence looks like — fast, focused, and deeply connected to our local supply chain.” Mike Tuffy, CEO, Optimas International.

“At Barton, we operate as one cohesive unit—when a challenge arises, everyone aligns with a shared purpose. That’s the strength of our team.” Frank Walsh, VP, Manufacturing.

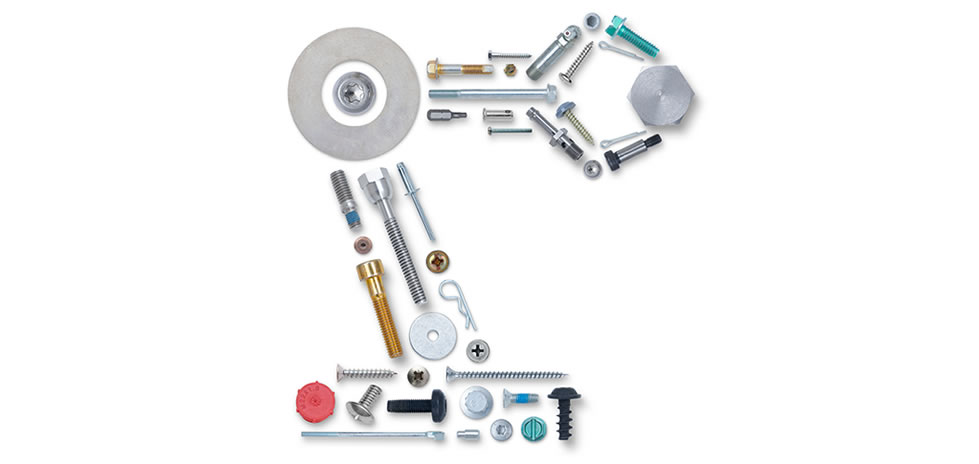

ABOUT BARTON COLD FORM

Based in Droitwich, Barton Cold Form is Optimas’ UK-based manufacturing arm specialising in the production of externally threaded fasteners. Its vertically integrated capabilities and close-knit supplier ecosystem allow for unmatched responsiveness and quality. 了解更多

下载案例分析