How to Transition to a Successful Nearshoring Operation for Fastener Acquisition

Making the strategic decision to transition to a nearshoring operation can bring about transformative benefits in how you acquire fasteners.

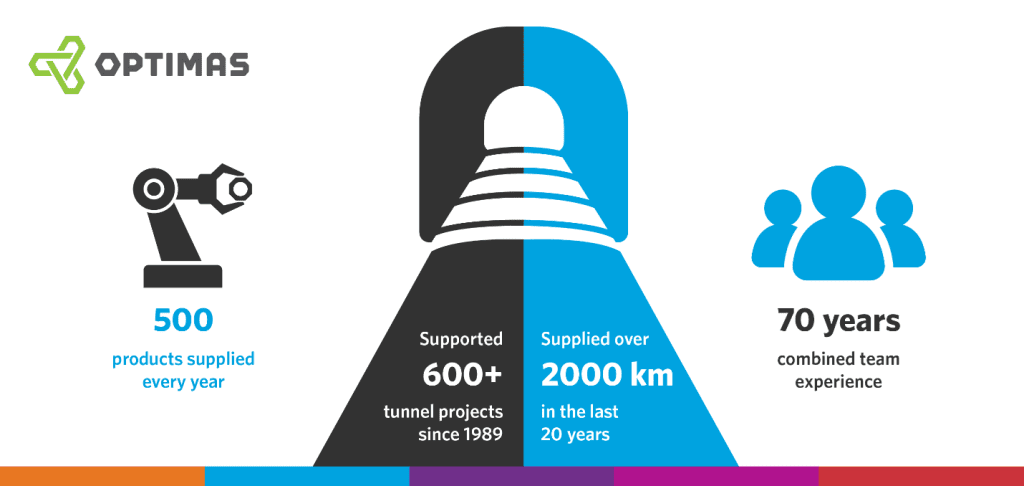

That is why Optimas customers are excited to discuss the cold form manufacturing facility we plan to open in Monterrey, Mexico in 2024. Last year, Mexico overtook China as the United States’ largest goods exporter base on recent trade figures, and we are excited to be giving our customers a competitive edge by getting their fasteners produced locally in the second half of 2024.

However, the process requires careful planning, evaluation and execution to ensure a seamless transition that maximizes the advantages of geographical proximity, cultural compatibility and cost-effectiveness.

Here’s a valuable guide we use to help customers navigate the shift to a nearshoring operation.

1. Assess Current Operations:

Before making the shift, conduct a thorough assessment of your current operations. Identify pain points, challenges, and opportunities that could be addressed through nearshoring. This evaluation will help you understand the specific areas where nearshoring can bring the most value.

2. Define Objectives:

Clearly define your objectives for nearshoring. Are you aiming to reduce lead times, improve collaboration, or cut costs? Defining your goals will guide your decision-making process and help you measure the success of the transition.

3. Research Potential Nearshore Locations:

Research potential nearshore locations that align with your objectives. Consider factors such as political stability, infrastructure, skilled labor availability, and legal regulations. Choose a location that offers the right balance of advantages for your business.

Optimas is actively seeking production orders with delivery dates in the second half of 2024 – complete this form to learn more

4. Select the Right Partners:

Choosing the right nearshore partners is crucial. Look for suppliers that share your values, have a strong track record, and can meet your quality and quantity requirements. Building strong relationships with reliable partners is key to the success of your nearshoring operation.

5. Cultural Compatibility:

Evaluate the cultural compatibility between your company and the nearshore partners. Shared cultural values and business practices can foster smoother collaboration. Ensure that communication styles and work ethics align to avoid potential conflicts.

6. Develop a Transition Plan:

Create a detailed transition plan that outlines the steps, timelines, and responsibilities involved in the shift. This plan should address aspects such as supply chain logistics, communication protocols, quality control measures, and employee training.

7. Communication and Change Management:

Effective communication is essential throughout the transition. Keep your stakeholders, including employees and customers, informed about the upcoming changes. Address any concerns or uncertainties they might have and provide training to ensure a smooth adaptation to the new processes.

8. Quality Control Measures:

Implement robust quality control measures to ensure that the quality of your fasteners is maintained during the transition. Regular site visits, real-time inspections, and quality assurance protocols can help you uphold the desired standards.

9. Monitor and Evaluate:

Regularly monitor the progress of your nearshoring operation and gather feedback from both your internal teams and nearshore partners. Evaluate whether the objectives set in the beginning are being met and identify areas for improvement.

10. Continuous Improvement:

Nearshoring is not a one-time change; it’s an ongoing process. Continuously seek ways to optimize your nearshoring operation. This could involve refining processes, addressing challenges, and capitalizing on new opportunities that arise.

11. Mitigate Risks:

While nearshoring offers numerous benefits, it’s important to be aware of potential risks. These could include currency fluctuations, regulatory changes, or unexpected disruptions. Have contingency plans in place to mitigate these risks.

Conclusion: Maximizing the Potential of Nearshoring

Shifting to a nearshoring operation for fastener acquisition requires a well-structured approach that takes into account your specific goals, challenges, and opportunities. By carefully evaluating potential locations, selecting the right partners, and implementing effective communication and quality control measures, you can make a successful transition that unlocks the full potential of nearshoring.

Learn more about transitioning your fastener acquisition to our world-class manufacturing facilities in the UK, US and soon to be MX, by speaking with one of our knowledgeable representatives.