Manufacture Confidence

by Elevating Quality

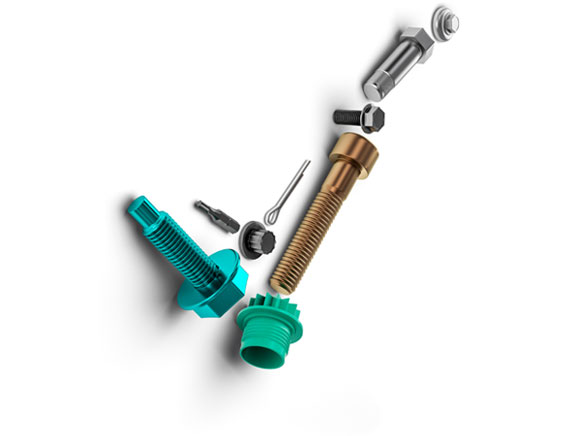

Optimas provides industrial manufacturing solutions, producing cutting-edge products your customers trust with “best-in-class” product range and zero-defect culture. We conduct a rigorous qualification process to ensure suppliers can manufacture high-quality parts at the volumes you need when you need them. We also work with our suppliers to continuously improve their performance and capabilities to better support you in every aspect of your supply chain.

Optimas Customer Success Metrics

Optimas supplies us with over 500 million fasteners to thousands of manufacturers globally.

They maintain a quality standard of less than 1 PPM.

– VP of Purchasing, Powertrain OEM

How is Quality Quantified?

These Optimas Resources Can Help

Where are Quality Impacts Seen?

These Optimas Resources Can Help

What Does Quality Look Like?

These Optimas Resources Can Help

Certified Quality Excellence

For state-of-the-art inspection, measurement and testing capabilities, Optimas leverages advanced technologies such as 3D printing to rapidly prototype and test your new and improved designs for trusted parts and greater reliability.

ISO-certified World Class Quality Labs

Optimas operates its facilities to the most rigorous standards as proven by our wide range of certifications and registrations:

In-House Testing And Inspection Capabilities

- Dimensional Analysis

- Metallurgical Analysis

- Case Depth

- Micro-Hardness Validation

- Chemical Analysis

- Performance Testing

- Coatings/Platings Thickness

- Pitch Diameter — Go/No Go

- Coordinate Measurement

- Pitch Diameter — Variable

- Decarburization

- Raw Material Validation

- Failure Investigation

- Spectroscopy

- Friction Coefficient

- Surface Integrity

- Hardness Validation

- Tensile Strength

- Hydrogen Embrittlement Test

- Thread Laps

- Surface Roughness

- Torque Tension

- Shore hardness testing — A & D

![]()

IN THE MEDIA: Optimas Re-Opens Quality Lab

Quality-Assured, Every Step of the Way

With deep expertise in fastening solutions and secondary processing, our mechanical engineering design services experts deployed across the globe can work with you to address a broad range of customer, industry and regulatory-specific requirements.

Global PPAP

Center of Excellence

Our Production Part Approval Process and our Global PPAP Centers of Excellence help companies keep their allotment of inventory, time, and money on track and their annual objectives within reach.

Complete Risk Management

Our Advanced Product Quality Planning (APQP), root cause analysis and Failure Mode & Effects Analysis (FMEA) diagnose, correct and mitigate process or product risk from development to product launch.

Lean Six

Sigma Programs

Our certified industrial manufacturing solutions experts are committed to using standardized global best practices such as Quality Core Tools and Lean Six Sigma to produce quality products in the volumes you need, delivered on time.

FAQs