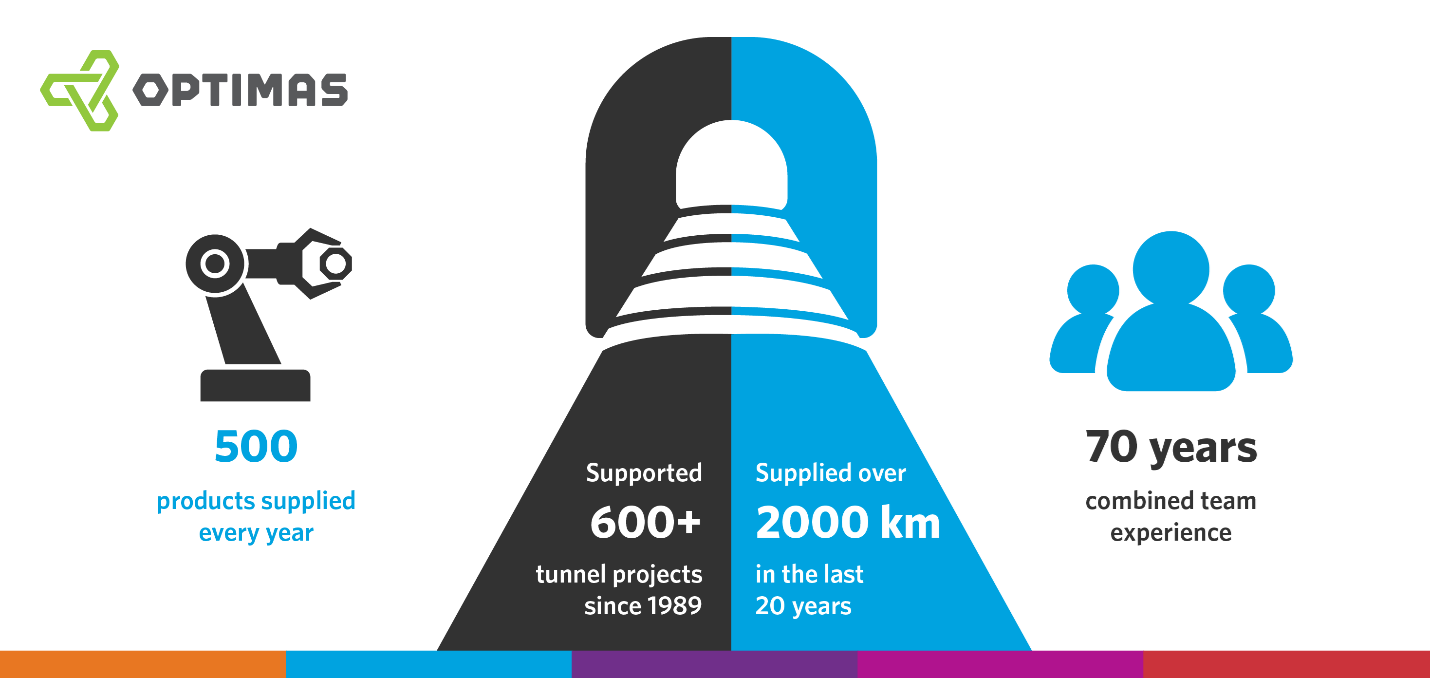

Optimas Sofrasar Tunnel Solutions in Numbers

Founded over 35 years ago in Sarreguemines, France, Optimas’ Sofrasar Tunnel Solutions has grown to be one of the largest global suppliers of tunnel components.

Optimas Sofrasar Tunnel Solutions has been supporting tunnel infrastructure projects with industry knowledge, design and engineering services, technical expertise and fastening solutions using a combined 70 year plus wealth of experience in the team.

The team support over 30 projects and supply around 500 products annually. Alongside their engineering and design expertise, this makes Optimas Sofrasar Tunnel Solutions a leading supplier for tunnelling projects. Projects have been supplied from 3m in diameter, all the way to the largest in the world – the Tuen Mun Chek Lap Kok tunnel in Hong Kong. Optimas Sofrasar Tunnel Solutions works in projects for sewer, cable tunnel, metro, railway and road tunnels.

The Optimas Sofrasar Tunnel Solutions main offices are based in North-East France, where the in-house team has a range of knowledge in engineering. From civil engineering backgrounds to plastic and metal engineering and of course tunnel, the team’s experience allows Optimas Sofrasar Tunnel Solutions to come up with adaptable and efficient solutions for a number of tunneling projects and requests.

As a result of the team’s wealth of expertise, they are able to develop and design bespoke products required for tunnel projects. This further strengthens the team’s adaptability to issues and allows for efficient solutions.

This can be shown when Optimas Sofrasar Tunnel Solutions simplified the construction demands of a sewage tunnel with highly specialized fastener solutions, which expedited schedules and reduced costs over the entire tunnel. The team designed and manufactured three bespoke parts which enabled more efficient construction, while removing ancillary components such as sockets for concrete anchoring. Each fastener was developed utilizing Optimas’ in-house testing labs, ensuring new components that were perfectly adapted for application.

In addition to the team’s main location in Europe, Optimas’ Sofrasar Tunnel Solutions has local tunnel representatives from across the globe, enabling them to meet requirements from Asia, all the way to South America. This global tunnelling expertise allows Optimas Sofrasar Tunnel Solutions to supply and support tunnel projects in over 25 countries.

Sustainability has grown to be an important factor in businesses across all industries, and this is no different for Optimas Sofrasar Tunnel Solutions. The guiding rods supplied are made from 100% recyclable material, which helps Optimas Sofrasar Tunnel Solutions and tunnelling projects utilizing these rods to help combat environmental challenges. 95% of tunnel products are made in France too.

Since Optimas Sofrasar Tunnel Solutions inception in 1989, the team has supported over 600 tunnel projects. In the last 20 years, over 2,000km of tunnel have been supplied.

The products supplied by Optimas Sofrasar Tunnel Solutions range from a number of systems and categories such as: the dowel system, bolting system, shear cones, guiding rods, grouting & lifting systems and more. See below for detailed information on the range of products supplied by Optimas Sofrasar Tunnel Solutions.

Bolting Systems

Used for the assembly of concrete segments, rail fixings and belt conveyors, the bolting systems supplied by Optimas Sofrasar Tunnel Solutions can support tensile stress from 70 – 400kN. Metallic inserts are made out of stainless steel, either 316L or a different grade as chosen through our design and engineering services. We offer various steel grade bolt options including ASTM A325 and 10.9, as well as zinc coated or hot dip galvanized.

Dowel Systems

Fixating the rings through thermoplastic dowels can enable a quick and secure installation in tight global tolerances while providing stability of the rings as a result of ground or grout injection pressure.

Centering Systems and Shear Dowels

Centering systems and shear dowels that speed and simplify installation of concrete segments and enable optimum control of the shearing stress up to 500kN. Thanks to the design and engineering expertise of the Sofrasar Tunnel Solutions team, the centering systems and shear dowels come in a range of dimensions and thermoplastic qualities to find the most appropriated deflection curves for application.

Grout-Lift Sockets

A large range of grout and lift-sockets provides a water-tightness screw cap up to 40 bars and a pull-out resistance up to 400kN.

Guiding Rods and Packers

These simple and cost-effective products control the position between the concrete segments, providing a good shear resistance and full control of tight tolerances and slip hazards.

Precast Accessories and Security Systems

Our wide range of systems includes plastic and metallic inserts for the installation of electrical equipment, fire protection products and RFID-based product traceability.

How We Can Support Your Tunnel Projects

Optimas Sofrasar Tunnel Solutions has a range of services and products to provide fastening solutions to your tunneling projects.

From engineering design support to responsive and efficient shipping, quality control and validation and testing, Optimas Sofrasar Tunnel Solutions has the ability to offer a variety of solutions all across your projects.

Get in touch with one of our technical consultants who can provide information on the next steps of how we can support your projects.