The Benefits of Consolidated Parts for Vehicle Interiors

As vehicle builds become more complex, manufacturers look towards a portfolio of consolidated parts to help make their supply chain more efficient.

This is no different for a vehicle interior manufacturer. From navigation systems to body panels, each aspect of a vehicles interior requires durable, high-quality fasteners.

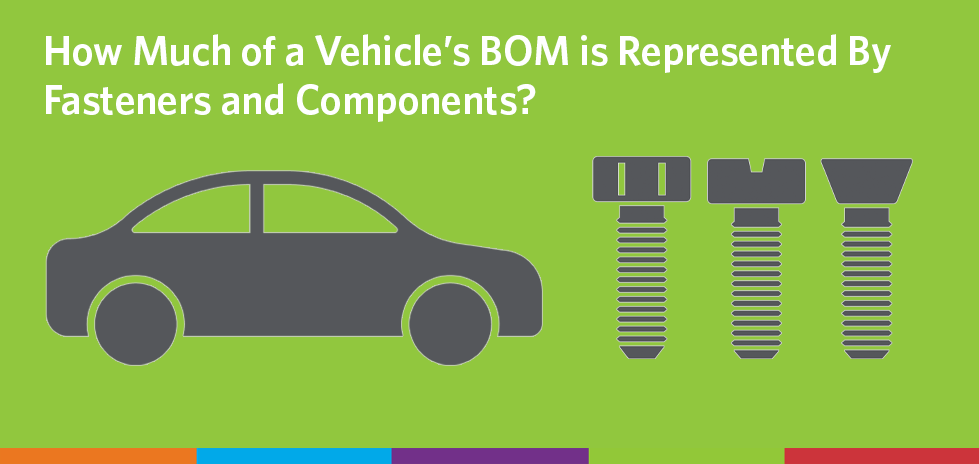

Making up around 50% of a vehicle’s bill of materials (BOMs), fasteners for vehicle interiors have a number of key conditions to satisfy, from passenger safety and comfort to technology user experience and vehicle performance. Therefore, due to the number of fasteners required to produce these vehicle builds, using a BOM of consolidated parts will help manufacturers improve their supply chain efficiency.

What Does Consolidated Parts Mean?

Part consolidation, also known as consolidated parts, is a term used to reduce the number of different parts in a build.

Multiple parts that come from more than one source increases the need for complex logistics and transportation. Plus, each separate part comes with a risk of delivery delays and confusion. These issues add greater complexity to the supply chain.

Therefore, consolidated parts can help lower the spend in these areas and improve supply chain efficiency.

Using Fewer Part Numbers

When manufacturing thousands of vehicle interiors, it can be challenging to keep the number of components low. Duplication of parts required often occurs when developing new products or iterations.

This is where partnering with a full-service supply chain partner can make a real difference. They can help you develop better custom components, use engineering support, 3D modeling and BOM refinement to routinely test and hone your components’ technical performance, lower operational expense and, most importantly, mitigate risk.

Optimas helped a Fortune 500 manufacturer to make their supply chain more efficient by reducing their initial BOM from an initial 152 components, where 54 new parts were required for the manufacturer’s newly developed product, all the way down to 109 with only 15 new parts required. The solution resulted in a 28%-part reduction and an overall cost saving of over $300,000.

Buying From a Full-Service Partner

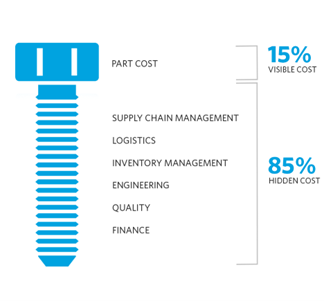

How you buy fasteners can significantly impact how you install and use them. 85% of the fastener price is unrelated to the part itself. That cost stems from the supply chain management and logistics that go into producing and shipping each part.

So much of vehicle production comes down to numbers. The part cost only takes up around 15%, where as the supply chain management, logistics, inventory management of the part and other variables equate to most of the total cost. Using a portfolio of consolidated parts can enable you to reduce these hidden costs and your overall total cost of ownership.

Accessing More Efficiently Designed Components

Out of the box fasteners can take up a lot of unnecessary space and are often bulkier than they need to be, particularly for the weight requirements in vehicles. Therefore, you can use a portfolio of consolidated parts to help improve your supply chain efficiency measures at the design stage to ultimately make your fasteners smaller and more cost-effective.

Working with in-house application engineers can help identify areas for improvement. For example, identifying the use of smaller parts (such as choosing an M6 over an M8, if applications allows) can provide benefits to improving weight, surface area and installation space. Partnering with full-service providers with in-house application engineers is a good way to utilize your BOM of consolidated parts and access the best components you need.

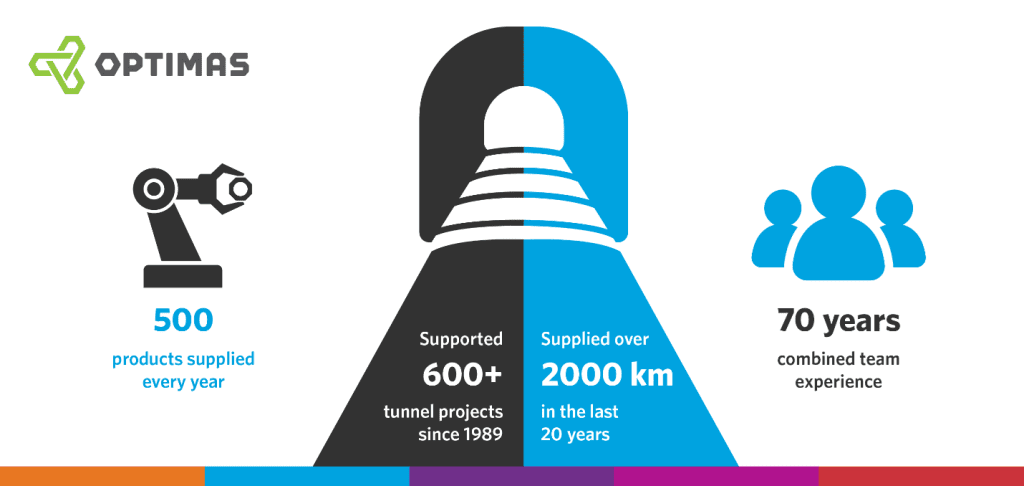

With decades of experience working with vehicle OEMs, Optimas’ engineers specialize in providing expert technical support to our customers, focusing on product development, analysis and testing to lower cost and assembly time, increase manufacturers’ speed to market and improve product performance.

Alongside catering for more specialized applications, we provide a wide range of standard fasteners for vehicle interiors, including but not limited to:

- Weld Nuts

- SEMs Screws

- Machine Screws

- Flat Washers

- Rivet Nuts

- Plastic Parts

- Headed Pins

- Flanged Fasteners

- And many more

Ultimately, it’s clear that there are lots of benefits using consolidated parts in the builds of your vehicle interiors. From reducing the size and cost of your products BOM, to accessing more efficient components from a single source, there are several positives to using part consolidation methods to help your supply chain efficiency.

Talk to one of our experts to find out how Optimas can help put in place several solutions to minimize the risk to your supply chain. At Optimas, we’ve built expertise in sourcing, manufacturing and engineering design, so companies can find and trust the solution that works best for them.

Still keen to learn more about our supply chain strategies? Check out how our part consolidation methods delivered long-term economic impact for a global truck manufacturer.