A commercial air conditioning manufacturer partnered with Optimas to re-engineer an electrical control box and significantly reduce part and manufacturing costs.

Annualized Real Results, Real Impact

$425,000

Inner Mounting

Plate Elimination

$60,000

Labor

Reduction

$8,500

Screw Consolidation/

Elimination

Background

An existing customer invited Optimas to explore a cost saving initiative relating to an electrical control box in a commercial air conditioning unit. Prior innovation failed to develop a fastening solution which would yield cost savings.

The original design of the control box enclosure contains a large steel stamping along with an outer casing that is installed on the face of the cabinet. This acts as a sealed unit to prevent leaks and moisture.

The internal plate is designed and manufactured with a large range of pre-pierced holes to house every potential electrical component configuration. On average, the customer only used 30% of the holes built into the electrical control box.

Challenge

A cost–and labor–savings initiative that eliminated an under–used part of an electrical control box in a commercial air conditioning unit.

Action

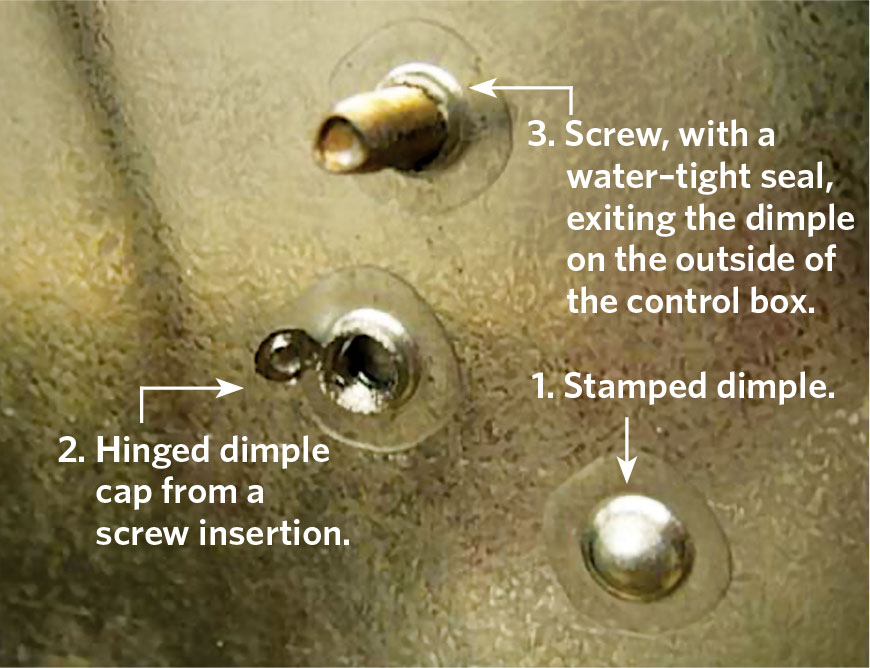

Design a “dimple” style fastening system, including a range of sharp-crested, thread–forming screws, that engages on contact with walls and:

- Adheres to UL production requirements

- Eases the mounting process during manufacturing

- Allows for “change outs” in the field

- Ensures a watertight seal

Results

- “Dimple” design eliminated the electrical control box inner panel and passed UL, weather and transit testing.

- Re-designed screws lowered the torque required for installation compared to standard thread-forming fasteners.

- Eliminated debris created or left in the joint during thethreading/installation.

- Field repairs/additional components can be made with standard machine screws installed into existing threads.

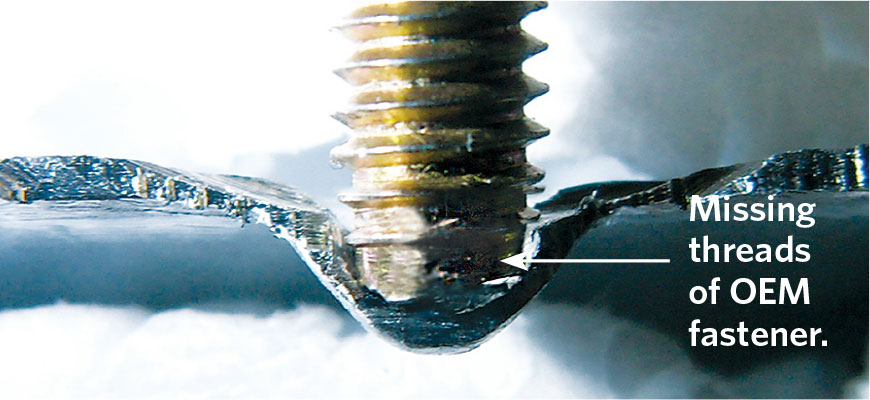

OEM Fastener: A standard trilobular screw can’t engage with a dimple pressed into the stamped metal wall of an electrical control box.

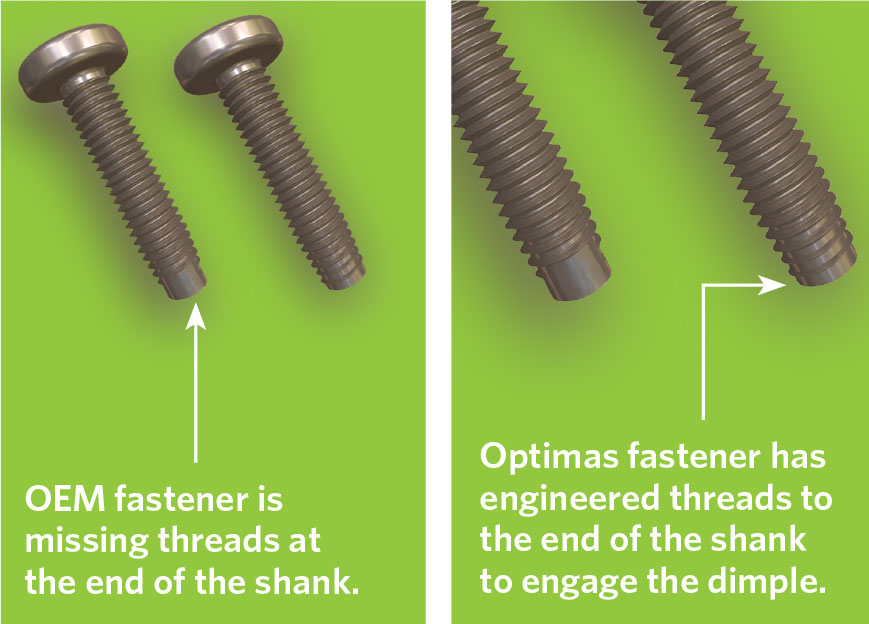

New Fastener: Replaced a trilobular, thread–forming screw (left) with a trilobular, sharp–crested, thread–forming screw (right) to engage the dimple.

Optimas Solution: Fastened components to the inside wall of an electrical control box and met all manufacturing and field-use requirements.

DOWNLOAD Case Study