Unlock the Full Potential of Inventory Management: How Automation Can Save You Money

Traditional inventory management systems, sometimes referred to as Vendor Managed Inventory (VMI), track how each part is ordered, delivered, stored and replenished. But a genuinely automated end-to-end system is much more significant in scope and benefits than just ‘managing parts.’

Digitized inventory management ensures you are working from current inventory numbers and less vulnerable to the disruptions and miscommunications multiple data sources can spark. In turn, automated solutions can help you more accurately anticipate stock levels required and elevate your chain planning for engineered fasteners and C-Class parts.

Still, some manufacturers cling to their legacy inventory management processes. Familiarity breeds comfort but remaining loyal to those routines are likely doing you little favors. In this blog, you’ll get more acquainted with what fully integrated inventory management can look like, how a digitized system saves you money, and small steps to get started.

What Does a Digital Inventory Management System Look Like?

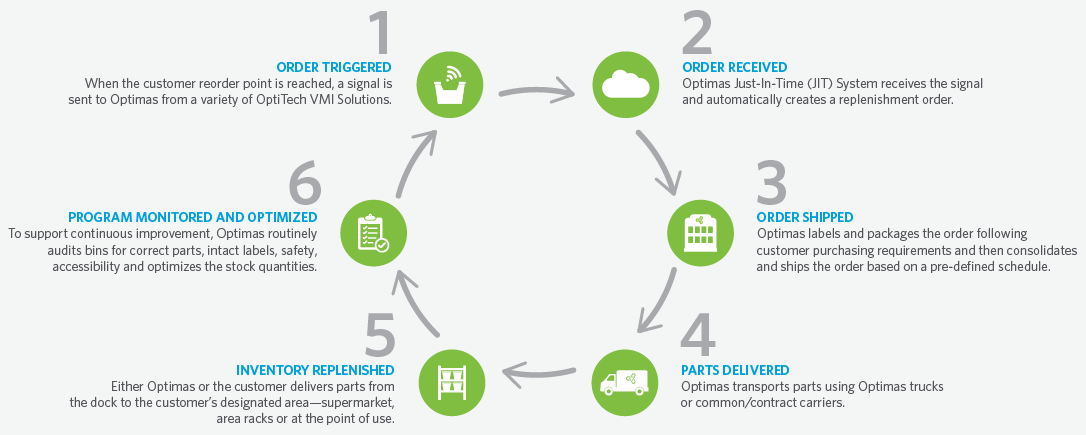

Below is a step-by-step representation of a proper end-to-end inventory management system.

Caption: Pictured above is the workflow for Optimas’ innovative OptiTech Inventory Management Solutions that use the latest technology to automate inventory replenishment. Learn more by clicking here.

How Does a Digitized System Help Me Save Costs?

An Industrial Machinery Digest study found that most companies devote 20% to 40% of their overall working capital to inventory alone. Keeping those costs down is critical to maintaining cash flow with such a sizable chunk of money invested in inventory.

Refocusing Human Capital

With a manual scanner or an automated replenishment system, it will take less time, teammates and process to maintain appropriate inventory levels. These productivity gains drive soft cost reduction and offer an opportunity to re-allocate people to roles with greater impact on production.

Better Forecasting Using the Latest Technology

Using RFID technology to manually or automatically submit replenishment orders means that your inventory may be monitored in real-time, and data can be utilized to create more accurate forecasts about your products’ future demand. As a result, you can modify production plans and inventory levels, as necessary.

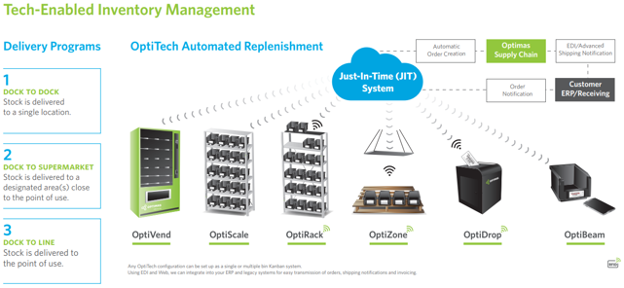

Caption: Pictured above are the multiple technology options at your fingertips with Optimas’ OptiTech Inventory Management Solutions Learn more by clicking here.

Working Smarter Not Harder with Business Analytics

Technology available today allows you to start capturing and using data and modeling based on real-time and historical consumption patterns. The best forecasting uses a mix of quantitative (e.g., past numerical insights and current market demand) and qualitative data (e.g., market trends, product lifecycle, competitive landscape, etc.) to guide more accurate inventory management decisions.

Additional Resources:

Optimas goes more in depth about how to use business intelligence to positively impact your bottom line. Read our articles featured in CIO Magazine here:

This foresight allows you to see where the demand comes from and plan accordingly. You can see where your fulfillment orders are, adjusting production and orders up or down based on product availability and lead time. See how this works in a video with Supply Chain Now and Optimas’ President of the Americas, Daniel Harms.

Automated inventory management leads to better stocking levels, which leads to less E&O (Excess & Obsolete), greater control over cash flow and fewer people needed to manage your inventory.

How Do You Get Started Transitioning or Enhancing Your Inventory Management System?

The first step is to identify your core pain points that a digitized system can help to resolve. Here are the top 5 questions to ask yourself to get started:

- On a scale of 1 – 10 (with 10 being the best) how accurate are your part counts?

- How long does it take to go from count to replenishment?

- Have stockouts occurred in the last 12 months?

- Has excess and obsolete inventory negatively impacted your company’s balance sheet in the last 2-3 years?

- Is your current supplier doing anything to support your inventory management process?

The answers to these questions can point toward the need for an inventory management solution.

Digitized inventory management can make your supply chain more efficient and resilient to disruptions, develop higher visibility into your part consumption, improve forecasting and help you reallocate resources to more productive responsibilities. It is all about spotting potential issues before they start.

There are many promises of inventory management. Today’s supply chain solutions and the right partner to plan, implement, report and fulfill orders can make those promises a reality.

As a practical starting point, we have put together a list of the Top 3 Things to Look for in a VMI Partner. You can also contact one of our inventory management experts to ask questions about transitioning systems. We will help you determine whether it is the right time to take this step and how to comprehensively compare your options to do what is right for your business.